SMEC’s Advanced Engineering and Machine Design:

- Cast iron structure for superior dampening characteristics and thermal displacement

- Rigid 45 degree slant bed design for heavy-duty machining

- Torque tube design to minimize bending and twisting

- Integrated box ways for long-term rigidity and heavy-duty machining

Please visit www.esmec.com or contact Ironclad Machinery for more information and pricing.

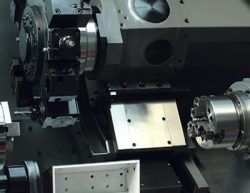

Did you know? One of the biggest advantages of SMEC’s lathes is the box way!

Box ways offer a great advantage over linear motion guide ways with respect to rigidity and load. In addition, box guide ways have a vastly superior vibration damping capacity over linear motion guides. They can be used even on very severe machining applications such as hard milling of pre-hardened steels and high nickel refractory aerospace alloys.

A further bonus with rigid box way machine tools is that they increase the life of today’s carbide and ceramic tooling by damping the vibration that can break tooling.

Box guide ways allow customers to push the part-load envelope, simply by reducing the rapid rates. Hence, box guide ways are always preferred when the application needs high load capacity, heavy rigidity, higher tool life, better vibration damping and ability to machine tough materials.

Learn more about the advantages of box guide ways here.

Other great features of SMEC lathes include:

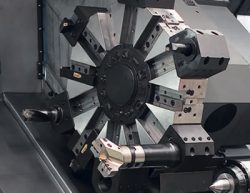

• EWS Turret which is used with all of the top lathe manufacturers in the industry.

• Superior Spindle Bearing design utilizing four rows of bearings.

• Superior design to maximize rigidity. Click here to learn about the benefits of Meehanite casting.

• Fanuc Controls, Drives, Motors

• Did we mention: BOX WAY!

Tight tolerances, hard material? SMEC has the solution!

SMEC Lathes

Head assembly with radiator fins to minimize thermal expansion.

The radiator fin structure of the head assembly minimizes thermal expansion of the spindle, preventing loss of precision due to increasing temperature. Also, thermal expansion is minimized with the symmetric design.

The spindle and headstock are machined and ground in a temperature controlled environment and assembled in a clean room. The precision double row cylindrical roller bearings and angular contact ball bearings are located in the front of the spindle, and a double row of cylindrical roller bearings is located in the rear to ensure heavy cutting capabilities with precision.

SMEC lathes utilize a hydraulic turret and a servo driven turret, depending on which model is selected.

Pre-tensioned and double anchored ballscrews are standard on any SMEC lathe. All axes ballscrews are pre-tensioned, heat treated and fixed by double anchors on both ends, providing ultimate rigidity and minimal thermal growth.

The programmable tailstock (carriage direct-coupled) is mounted on wide guide ways to ensure rigid work piece support.

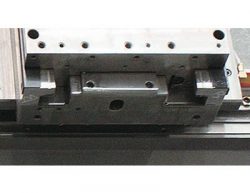

Hexahedral Slide Way Frame

Wide integral way is machined from the casting, induction hardened and precision ground to ensure long-term rigidity, machining accuracy and heavy-duty machining.

SMEC SLV-80/M